What is required to build a Rail Simulation Model?

A rail simulation model is a crucial tool for understanding and improving rail systems’ performance. These models simulate the train movements and operations on a rail network, allowing planners and operators to analyze the system’s behavior and make informed decisions to improve its efficiency and safety.

A model typically consists of several components, each representing a different aspect of the rail system. The following are the critical components of a rail simulation model:

Track Infrastructure Model

Track infrastructure is a critical component of a rail simulation model, as it affects train speed, rail capacity, and safety. The track infrastructure data required for a rail model includes:

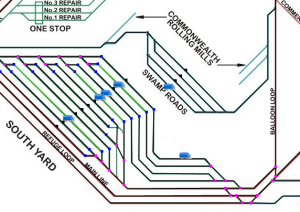

- Track geometry, including locations of depots, yards, passing loops, signals and travel times

- Track structure e.g. single/double/triple track, movement rules

Rolling Stock

Rolling stock is another important component of a rail simulation, as it affects train performance and network capacity. The rolling stock data required for a rail simulation model includes:

- Train length, number of wagons, wagon capacity

- Maximum speed

- Train type e.g. diesel/electric

- Fuel capacity

Train Scheduling

Train scheduling is an essential component of a rail model, as it helps to optimize train movements and avoid delays. The train scheduling data required for a rail simulation model includes:

- Train timetable, including train departure and arrival times, and train frequency

- Train speed restrictions, including those imposed by track geometry or signaling system

- Train priority rules, including those for freight or passenger trains

Simulating Maintenance

Maintenance is a crucial component of a rail model, as it ensures that the rail system remains in a state of good repair and operates reliably. The maintenance data required for a rail simulation model includes:

- Maintenance schedule, including the frequency and duration of maintenance activities

- Maintenance types, including preventive maintenance, corrective maintenance, and predictive maintenance.

- Maintenance resources, including labor, equipment, and materials needed to perform maintenance activities

Maintenance activities can include track maintenance, rolling stock maintenance, signal system maintenance, and other types of maintenance needed to keep the rail system operating reliably. By modeling maintenance activities in a rail model, planners and operators can ensure that the rail system operates reliably and avoids unplanned disruptions that can affect safety and efficiency. Track maintenance can fully close one or more tracks, or apply speed restrictions to certain parts of the network.

Rail Simulation and Dispatching

Dispatching is an essential component of a rail simulation model, as it involves making real-time decisions to manage train movements and maintain system capacity. The dispatching data required for a model includes:

- Train dispatching rules: this may be based on a timetable, a minimum headway between departures or run when ready

- Demand consideration: if a rail network is servicing numerous locations such as a coal network, the dispatch logic will ensure trains are dispatched to the mines evenly according to their demand

- Other network considerations: trains can be dispatched to ensure they do not not exceed the capacity at their destination and will not have lengthy delays on track by encountering planned maintenance.

Conclusion

Rail simulation modeling is a powerful tool that can help rail planners and operators understand and improve the performance of rail systems. To create an accurate simulation model, planners and operators need to gather and use the relevant data for each component of the rail system. By understanding the critical components and data requirements of a rail simulation, planners and operators can use the model to optimize the rail system’s efficiency and safety.

InterDynamics has built numerous rail models for clients in the freight industry around the world. Contact us to discuss your requirements and our team will let you know how Planimate can help.