Iron Ore Supply Chain Simulation Case Study

What was the problem?

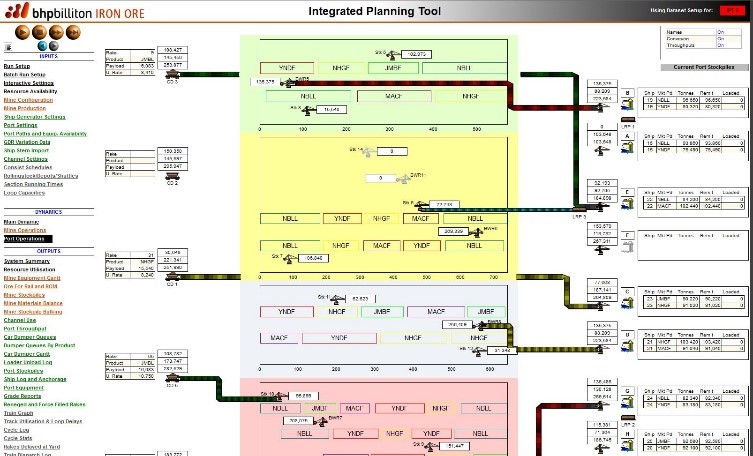

Port Operations screen of the Simulation Model

BHP’s Western Australia Iron Ore supply chain consists of seven mines, more than 1,000 kilometers of rail and two separate port facilities. As they were rapidly increasing production the complexity also increased. This was due to the addition of new infrastructure, new products and introducing blending at the port. It was identified that a simulation model of their supply chain was required to assist the planning group for both long and short term capacity planning and scheduling.

What did we do?

InterDynamics created The Integrated Planning Tool which is a simulation model of the full Iron Ore supply chain. This pit to port model included mine processing, train loading, a full rail network through to unloading at the port, stockyard operations, shiploading and the channel. The model allows for shipstreams to be imported or built using nominal demand data. Each piece of equipment could be configured including availability and variability around processing rates.

The railway could be simulated in different modes e.g. run when ready, daily rail schedule or demand driven to cover every operating possibility. The rail fleet could also be configured to allow changes to train length, weight and speed. Network changes were also considered to enable testing more or less capacity at different locations on the railway. Our Planimate simulation software allows easy changes of track section from single to dual to triple track, additional passing loops etc

The full stockyard at the port was also modeled to allow for analysis of different scenarios. The users could modify stockpile sizes, product and stockyard allocations and blending rules. Port infrastructure including conveyors, stackers, reclaimers, car dumpers and ship loaders were all included in the simulation software to ensure the impact of their availability and production rates could be analysed and measured.

Planned and unplanned maintenance was also included in the simulation model. This assisted in the alignment of maintenance across the supply chain to minimise production impacts. It also enable the planning group to measure the impact of proposed changes to any planned maintenance.

Put simply, this simulation software allowed the planning team to understand the supply chain better. As a new piece of equipment came online it could be modeled in the supply chain to give them confidence in how it would affect schedules, availability, inventory levels and throughput. Despite the increased complexity the simulation model enabled them to increase their planning accuracy.

The InterDynamics team are experts in designing and delivering supply chain simulation software. Contact us today to find out how we can get more out of your supply chain.