Supply chains can be complex with many assets operating between numerous interfaces. A well-managed supply chain ensures that the right products are delivered to the right customers at the right time, all while minimizing costs and maximizing efficiency. However, managing a complex supply chain can be a challenging task, especially when it comes to making decisions that can affect the entire chain. This is where supply chain simulation software comes in, and with a comprehensive software development toolkit, the InterDynamics developer team are ready to help.

Optimize Your Supply Chain with InterDynamics' Simulation Software

What is Supply Chain Simulation Software?

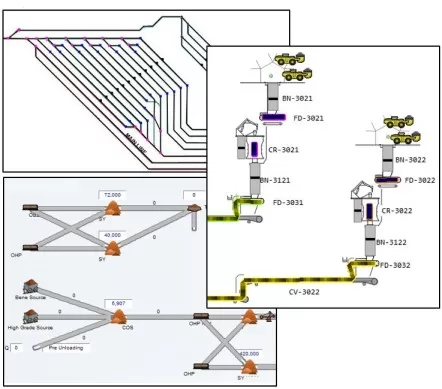

A key offering is discrete event simulation software developed by InterDynamics. It enables businesses to simulate and analyse their supply chain processes, allowing them to make informed decisions that can improve efficiency, reduce costs, and increase system throughput. With simulation, businesses can model their entire supply chain from start to finish, from pit to port, from the raw materials to the finished product, and everything in between.

Every supply chain and logistics network is different and InterDynamics develop supply chain simulation software that is 100% customized to your requirements.

How Can Supply Chain Simulation Software Be Used?

The InterDynamics developers can assist you to better manage your business’s supply chain. Here are some examples:

1. Forecasting

Forecasting is an essential part of supply chain management. Accurate forecasting enables businesses to predict future demand and adjust their supply chain processes accordingly. We can analyse and simulate your data to create accurate forecasts based on historical data, market trends, seasonality and other relevant factors. This enables clients to optimize their inventory levels, production schedules, and other supply chain processes, ensuring that they have the right products in stock when customers need them. While Excel is useful it cannot replicate your operation to determine losses at interfaces, or the impact of queuing or variability.

2. Capacity Planning

Capacity planning is another critical aspect of supply chain management. Using simulation, businesses can model and simulate their operations and determine if it has the capacity needed to meet demand considering any constraints. This allows businesses to adjust their production schedules and processes to ensure that they can meet demand while minimizing costs.

3. Feasibility Studies and What-If Scenarios

Another key benefit of simulation is the ability to perform feasibility studies and create what-if scenarios. Businesses can model different scenarios to see how changes in their supply chain processes will affect their bottom line. What if demand increased? What if we carried less inventory? How long do we take to recover after major interruptions? This allows businesses to make informed decisions about which changes to implement and which to avoid.

We are able to create detailed simulation models of brownfield or greenfield operations. For a brownfield site, we can create your existing operation and then add in all of your planned expansion options to test and measure the potential improvements.

For a greenfield site, we can simulate the project as it is designed or with additional features or constraints. This allows you to understand the sensitivities of the operation before finding out the hard way.

4. Variation Modeling

Supply chain processes rarely run perfectly to schedule. Simulation allows you to model the variation in your supply chain processes. By modeling variation instead of planning with averages, businesses can identify potential bottlenecks and inefficiencies in their supply chain and take steps to optimize their processes that improve efficiency and reduce costs. Simulation modelling will allow you to perform data based analysis such as how much additional inventory do we carry due to variation of poor scheduling.

Our Experience in Supply Chain and Logistics Management

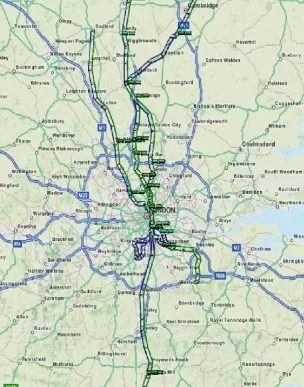

InterDynamics has been providing supply chain simulation solutions to businesses for over 30 years. We have a team of experienced professionals who can work with you to identify bottlenecks or opportunities for improvement in your supply chain processes and help you implement solutions. InterDynamics’ expertise in supply chain simulation software has helped businesses across a variety of industries, including mining, logistics, port and rail, to optimize their supply chain processes and improve their bottom line.

Example clients using our services are:

- a below rail operator managing a coal network

- an Iron Ore miner testing new operating scenarios to improve their mine and railway productivity

- a rail operator planning terminal movements

- a pit to port mining operation analysing feasibility studies for infrastructure upgrades

InterDynamics build valuable yet affordable systems by focusing on what matters. If you have supply chain components that are sound and reliable then those processes do not need to be modelled in detail e.g. it may be appropriate to have a simple rail yard delay that accounts for queuing, unloading, provisioning etc. If that yard was problematic it can be modeled in great detail to allow greater analysis. We work with you to get the maximum return on your investment.

Ready to start a conversation about Supply Chain Simulation Software?

If you’re looking for a way to optimize your business’s supply chain processes, discrete event supply chain simulation software is an excellent solution. With InterDynamics’ experience and support and modern software toolkit, you can take control of your supply chain. Whether you need help with forecasting, scheduling, expansion studies or capacity planning, or any other aspect of supply chain management, the InterDynamics team can help.